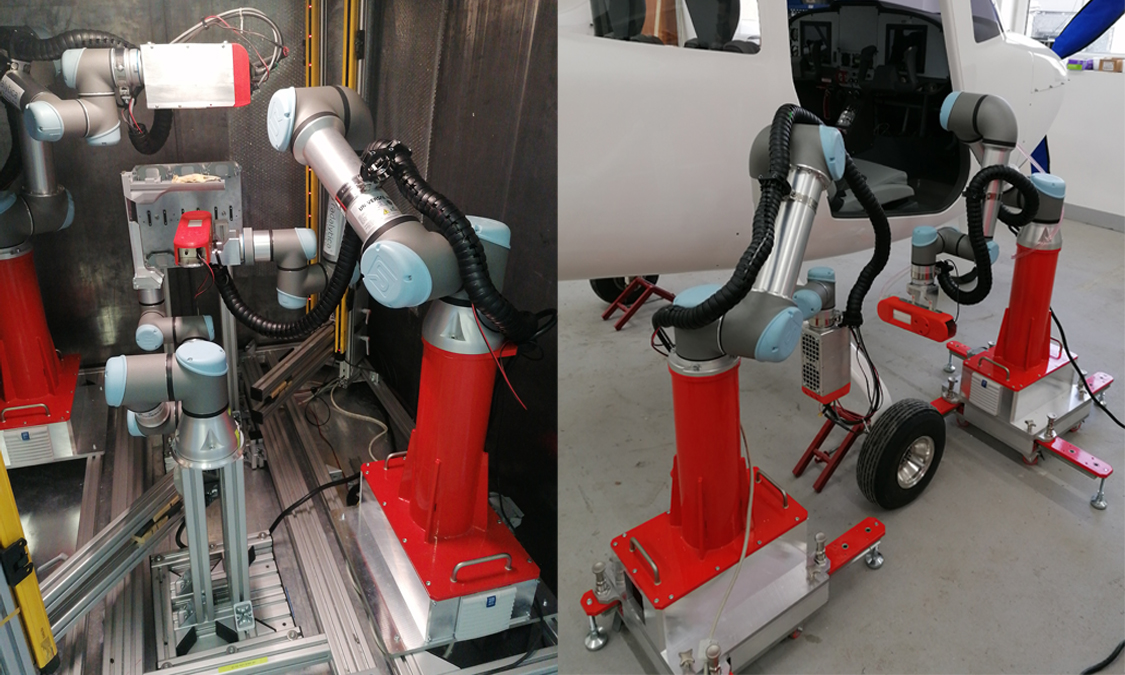

Fig. 1 Photography of the existing robotic scanner RadalyX for general inspection applications. The devices allows large area 2D and 3D scans, computed-tomography, tomosynthesis and real-time X-ray inspection.

X-rays reveal internal structures of inspected samples. Both the X-ray tube and the detector

in classical X-ray imaging systems are fixed or can move only in a limited range of directions

(up/down/left/right). There is typically no flexibility to rotate about an arbitrary axis, i.e. look

at the sample from different angles. Common is only rotation about one axis for Computed

Tomography.

Contrary to the classical X-ray system, the robotic one allows nearly arbitrary flexibility of view angles.

• integration of direct conversion photon counting X-ray detectors,

• high resolution (55 µm or better1) imaging of large objects,

• real-time imaging with immediate viewing angle and position control,

• variety of scanning modes for different sample types,

• arbitrary plane of scanning or scanning over a complex shape,

• spectral X-ray imaging for material identification.

The key parts of the scanner are two robotic arms with 6 joints. The first arm holds an Xray tube, the second holds an imaging detector. The X-ray tube/detector pair can, thanks to the robots, move and rotate freely about the sample. The robots are moving synchronously so that the mutual position of the X-ray tube and detector remains the same under all circumstances.

X-rays reveal internal structures of inspected samples. Both the X-ray tube and the detector in classical X-ray imaging systems are fixed or can move only in a limited range of directions (up/down/left/right). There is typically no flexibility to rotate about an arbitrary axis, i.e. look at the sample from different angles. Common is only rotation about one axis for Computed Tomography.

The automatic scanning modes are used to create an overall image of the inspected sample. The system can be switched to a real-time imaging mode where the robot position and orientation is controlled via a 3D mouse.

The 3D mouse allows the full control of position, pitch yaw and roll of the X-ray image view. The X-ray image of the

given sample area is shown in real-time on the screen. The smooth manual control of the view with the online

image stream creates a perfect tool to localize defects in the inspected structure in 3D.

The real-time imaging is shown on videos under this link:

The immediate feedback between the manual view direction control and the X-ray image is what makes the system very intuitive to use. Thanks to the link between the image and our action the brain is able to create a

very clear idea about the 3D structure of the sample without the need of usually slow,

complicated and high-dose measurements like computed-tomography (CT) that requires

similar approach in the analysis of acquired 3D volume anyway. Therefore, inspection with

robots is compared to CT faster, less demanding on the data processing and can be

applied to a selected area of a larger object.

We are developing systems that give customers the best X-ray imaging quality and provide complex modularity of the most advanced imaging methods for non-destructive inspection of different samples and materials.

X-ray view can be controlled online using a 3D mouse. Position, pitch, yaw and roll of the view can be smoothly changed while observing real-time X-ray images.

The integration of imaging technologies on six-axis robotic arms gives imaging the possibility of great flexibility in terms of size or shape of the sample.